Great question.

A camshaft is a shaft which has one or more cams attached to it.

A shaft is a long narrow(solid cylindrical in the case of the camshaft) rod.

A cam is a projection on a rotating part in machinery,

designed to make sliding contact with another part while rotating and to impart reciprocal or variable motion to it.

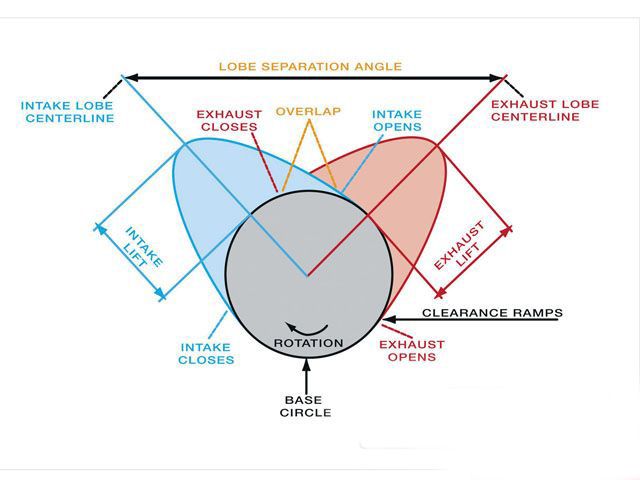

A camshaft converts rotating motion of the shaft, to reciprocating motion of the valves.

The camshaft does this by having a cam lobe to contact each valve tip.

As the camshaft rotates, for much of the rotation the cams are at "zero location".

When the cam begins to become thicker, this is the "lift" beginning to take place.

The amount of time the lobe(or cam) is creating lift, is called "duration"(measured in degrees of rotation of the crankshaft).

The camshaft on the Chrysler 2.2/2.5 engines is an "over head" camshaft,

and it is located over the cylinder head, attached to the cylinder head with "cam caps"(similar to crankshaft "main caps").

The camshaft rotates by a toothed gear("cam gear") attached to the front,

which a belt(timing belt) is attached to.

This belt is also attached to a gear which is attached to the front of the crankshaft(crank gear).

These 2 gears must be "timed" for proper valvetrain, and overall engine operation/performance.

Below is an illustration of the operation of a valvetrain similar to our TM 8 Valve engine.

(Camshaft and gear in green)

.

Reply With Quote

Reply With Quote

TD is still taking shots at TM but I haven't seen any on here for awhile, at least that's a start.

TD is still taking shots at TM but I haven't seen any on here for awhile, at least that's a start.

)

)