So I snagged a couple of these from a dealer I use to work at with the thought that someday I would use one to build a exhaust cutout. they measure out to over 3"! I am not sure how the ECU controls them, or why they even have them but they are a aluminum body with a SS butterfly and throttle shaft. Very beefy! When I tore one apart it had a circuit board that had obviously had the smoke let out of it, and a 380ish sized electric motor with a decent amount of gear reduction. Pretty cool part and thats why I saved them from the scrap bin. This is what they look like.

I have had a problem with the local po-po's and the not very loud exhaust on my turbo neon. The way the law is written the only way to make it legal is to put a stock muffler on it, and I hate to neuter the car! Ive been toying with the idea of putting a exhaust cutout on it anyways, because I wanted more flow but didnt want to spend the $$$ on big exhaust and mufflers to make it tolerable since the car is my DD. Ive came up with many diffrent ways off opening and closing one of these throttle valves, from a cable to using a modified window regulator. But I wasnt happy with any of them. I also didnt want to use a off the shelf cutout because they are expensive, and even the good ones seem to fail. There is a reason they sell replacement motors for the good ones.

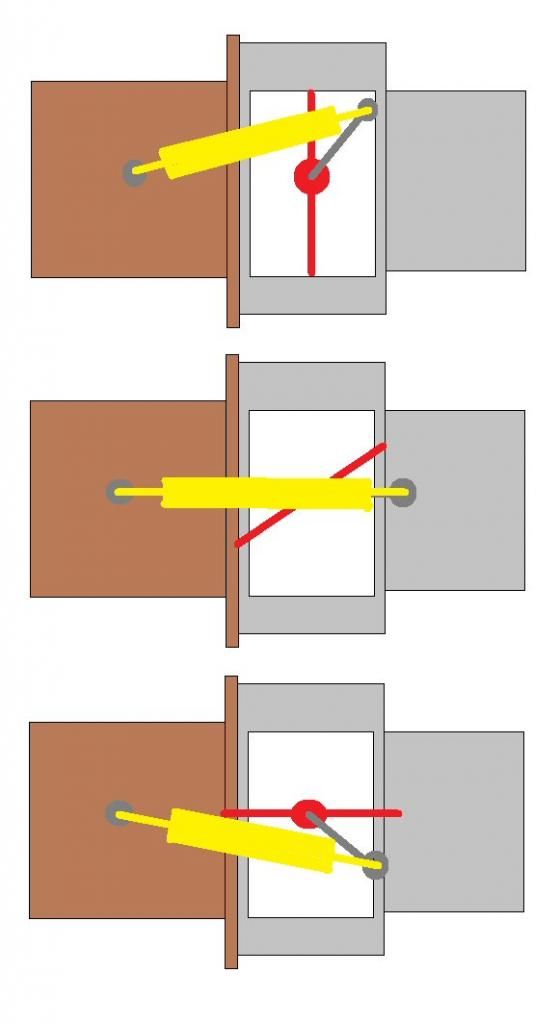

Then today I had a epiphany! I had always planned on tossing the motor/gears the throttle valves came with because they are straight gears not a worm drive so just opening or closing the valve with the motor would not have kept it open or closed. But then it hit me, why not build a cam type spring system to hold it open and closed? So with it open or closed the spring puts pressure on it to keep it where I want it! The motor will open and close it, it will just have to have enough power to overcome the spring, but once it does the spring will slam it open or shut. Nice and simple. The motor/gear assembly is sealed so it should hold up fine to water/dirt that the underside of a car see's. Obviously I will have to extend the throttle shaft and come up with a way to seal that, but I don't see that as a huge problem. Here is the system I came up with. The top pic is closed, middle is with it half open, the bottom is closed. Its MS paint, so its not really to scale or anything, but it gives you a idea of what I am planning.

Brown is the exhaust pipe

Grey is the throttle valve

Red is the butterfly

Yellow is the spring

So hows it look to you guys? My only fear is that I will have to use too heavy of a spring to keep it closed and not blow open. But since the shaft is centered it shouldn't take very much force to keep it closed should I? The motor is a 380 sized but is very long and should have good TQ. Obviously I want to use the lightest spring possible to keep the load off the motor as much as possible. These do have a built in return spring in them that is pretty beefy (that I will be removing) so I don't think it will be a big problem. I also think these should have been designed for a million duty cycles so I would think that me only using the motor to open and close it, it should last forever. W.P._Turbocars has been using a modified TB as a cutout for years with no problems and this thing is much beefier then a TB.

So thoughts? Will it be a massive failure or a great success? Once I start modding it I plan on taking pics and will be updating this thread so others can do the same thing, unless someone finds a massive flaw in my plan and I abandon the project and go another route.

Reply With Quote

Reply With Quote

12.57@104 :O)

12.57@104 :O)