Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

You can block off all the openings in the high res section of the shutter wheel and then use a sharp knife to cut out one section in the spot you want the cam pulse to be. You could also do the same thing with the low res area of the wheel but then you won't be able to use it as a crank trigger anymore.

If it was me, I'd use a crank sensor and then use some foil tape to block off all but one cut out in the low res shutter wheel to use as a cam sensor.

if I were you I would add a 36-1 wheel on the crank, then do a half moon shutter wheel on the distributor. best possible signal setup for MS- no limitations on timing. I made a jig for the 36-1 wheel to align it with the crank pulley and welded it on- worked perfectly and was not hard to do. for the half moon cam shutter wheel I just took a N/A distributor and cut all the teeth off the shutter wheel, made a half moon shutter wheel out of a 2" exhaust pipe connector that I bought from Autozone PN 17504 cut it to size with a chop saw and welded it to the original shutter wheel base. that was also pretty easy.

the end result is nearly instant sync as soon as you hit the key, and the most accurate timing setup you can get

I would not attempt to use two sensors at the same time from the distributor. If I wanted to be that accurate I would want to take out the timing belt deflection from the equation.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

Well, you could easily convert the distributor pickup to the half moon style mentioned above. Then add some manor of crank position sensor. A 36 tooth wheel is overkill for ms2 but can be bought off a shelf but as I've mentioned i found it super easy to mark up my damper with some ink and a scriber and a drill press. A 6 or 12 tooth wheel would work great a six cylinder without putting much effort into it. i used a piece of angle aluminim to mount a crank sensor towards the front of the motor under the distributor. I found that a hall effect cam sensor from a 2000ish madza 2.0 worked great as a low resolution crank sensor; salvage yard parts work great for mockup and testing. The half moon distributor and a 12 tooth crank gives all you need for a great wasted spark setup..... or just run the crank sensor and the distributor/single coil.

I found today that my setup as is was able to physically spark farther then -10 ATDC timing and ~50 degrees BTDC.

Now I am going to mess around with adjusting things. I don't know if it was the reasoning behind your original plan to run trigger return but that suggested setup of yours is supposed to provide the good starting of cam phasing around 5-15 degrees BTDC and have the good running and adjustability of setting it between 60-90 BTDC.

I only see upgrading from camshaft only to include all the mods required to run sequential fuel injection and coil on plug ignition. I really don't think I have the ability around here to get a spark tune close enough to need greater accuracy without spending the money that would make a weaker ignition setup pointless. So I think if I get stuck someday with ignition blowout (especially caused by high rpms) then I will then move to upgrade my Tach In setup.

My distributor setup right now really kills off my dwell time at higher rpms. Not sure what rpm it will have problems at without boost but I have a feeling that boost + 8500 rpms (goal) will not work. I will probably try boost a coil first and run the coil at higher voltage when I get there before upgrading the entire ignition system. I think I would also give a hotter coil a chance.

3000gt guys have problems with their wasted spark blowing out in many 500+whp setups but its hard to say how good of a job they are doing to minimize problems on the setups in the lower range of HP. I had to use small spark plug gaps with OEM ignition and then had to go even smaller as HP rose. Alcohol injection also makes spark blowout happen at even lower HP levels. Spraying 3 nozzles makes it really bad.

Last edited by Ondonti; 06-30-2014 at 11:12 PM.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

I really failed at this.

Pretty sure there is a typo for falling edge instructions from 87turbodance but...

I was lazy so I only put my degree wheel on and set it to zero based on the camshaft arrow to timing cover mark.

================================================== ===========================================

Then I put the crankshaft to 10 degrees BTDC

Forced to enter trigger return spark mode and enter an offset higher then 60 or it caused configuration errors in ms2/extra 3.3.1, Set offset to 75

Falling edge

Set middle LED indicator to Ignition trigger indicator

---------------------

Now, turned back distributor backwards until LED turned off. Slowly turned forward until it turned on. Its almost exactly where it was when I used a 15 degree offset and a timing light to set things up with basic trigger. Locked down the distributor.

-----------

Set fixed cranking timing to 10

Set fixed timing to 10

Left predictive timing on.

Verified rotor was just about to leave #1 terminal at 10 degrees BTDC

-----------------------------

Left in trigger return mode and falling edge

Tried to start and got a few nasty backfires. Tried again and it started.

================================================== ===========================================

Megasquirt is commanding 10 degrees timing BUT my timing light indicates something like 30 degrees ATDC (retarded).

Should have taken a datalog.

Seems like a big failure.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

Here is the only description I have read of trigger setup that has actually been clearly explained.

This refers to setting up an Audi distributor but its basically the same as the 3.0 12 valve SOHC distributor except the inner optical data is from 5 small and 1 large window slots while 3.0 6g72 12 valve is 6 equally spaced large slots. Both have outer 360-10 slots.

Looking into this also lead me to the Nissan CAS which has replacement distributor (50 and 54mm) slotted discs available on DIY's website that are megasquirt compatible with full sequential. I might try one of these in the future. I don't think the ECU can handle our high data 360-10 slot setup. I did think that we could just cut out groups of slots in the OEM and create a 36-1 wheel. I did not measure our OEM wheel to see if its 50 or 54mm. They mention possible compatibility with Mitsubishi applications.

http://www.theprojectpad.com/viewtopic.php?f=14&t=796

And something that bothers me with what I am doing right now,Originally Posted by vt10vt

Guy who is said to be THE Audi megasquirt guy with additional electrical engineering backgroundOriginally Posted by vt10vt

Trigger return is supposed to be good in that it allows you do use one side of the slot for cranking and another slot for running. That avoids the tradeoff where trigger angles of 0-5 degrees BTC only provides high quality starting and 60-90 provides the best running characteristics.Originally Posted by elaw

This might be why so many people were running rising edge instead of falling edge...So the 3.0 megasquirt install guide by 87turbodance still does not make sense for rising vs falling edge. I know Kyles MS3 functions with 75 offset, his distributor alignment looks the same as mine, and he uses falling edge and trigger return. Mine does not work as is.

I need to go record what angles the Middle LED trigger indicator turns on and off at in the 0-100 BTDC range. Then figure out if I can use trigger return or if I have to use basic trigger and also figure out if I need to use rising edge instead of falling. Having had apart my messed up optical setup in my He341 3.0 Spirit, I know there is some adjustability in the slotted disc and also the rotor if I really needed to. I could force more adjustability in worst case scenario.

Last edited by Ondonti; 07-03-2014 at 12:35 AM.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

With distributor setup to be about "normal" compared to 2 other 3.0s,

--------------------------------

Trigger turns on with falling edge trigger return

ON 130 to 75 BTDC

Off 75-10 BTDC

ON 10 BTDC - 45 ATDC

---------------------------

So I think I need to use rising edge since the setup instructions want your LED to turn "on" during the 75-10 window, not off.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

This is kinda making me grumpy with megasquirt even more since the best descriptions date back to MS1 stuff and it seems that people are given less and less "why" along with the newer stuff, even when the same circuitry is used.

http://www.msextra.com/doc/ms1extra/...ED_for_IRQ.htm

Originally Posted by MS1 extra manual

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56

You can setup MS to "trigger" on either the slots on the pickup wheel or the filled in parts of the trigger wheel. The trigger angle will be the beginning of the opening or gap and the trigger return will be either the ending of the opening or gap. Try to get the of transitions of the beginning or ending of the gap to line up with about 0 degrees btdc - this will make a great trigger return angle for starting. Then rotate the motor backwards until the middle LED changes to indicate that you have reached the other end of the opening or gap - this will become your trigger angle. Then get your spark tower terminals to line up with the trigger range you've setup.

I have to change my chart now to reflect that those #'s were taken with falling edge and maybe make another showing rising edge. I changed the setting to rising edge and then my 10-75 degree BTDC window is ON instead of off. Falling edge vs rising edge just changes weather megasquirt is looking for voltage to be high or pulled low so changing the setting will "flip" the range that is considered "ON"

Now timing sets at 10 degrees with a slight distributor adjustment (could have used trigger wizard and changed my crank offset).

Very happy.

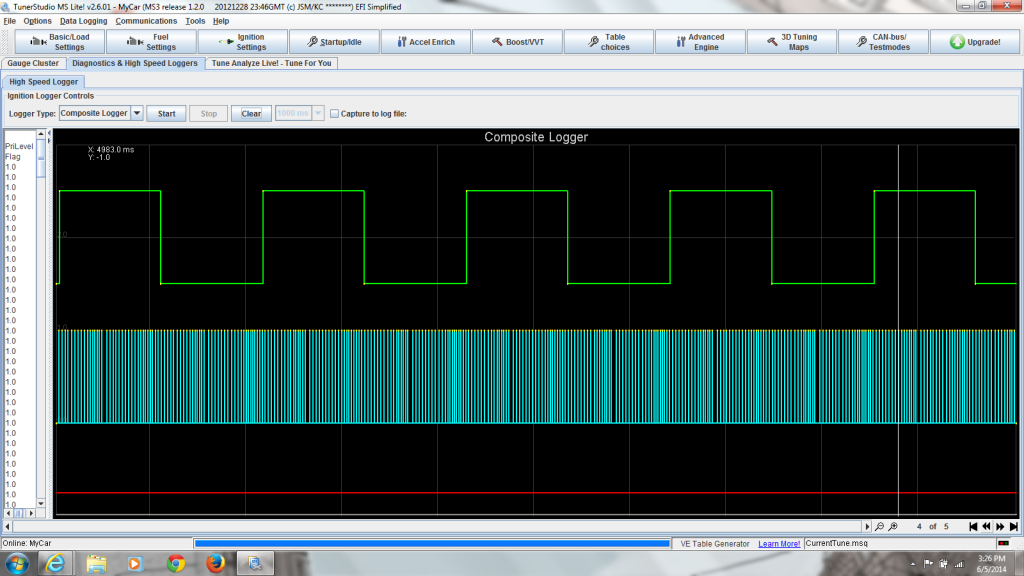

Then took a datalog of some 4th of July antilag afterfires.

My timing is now able to go to -10 degrees during antilag(when not cutting sparks). Idle timing control is now also able to go below 16 degrees (previous limit with basic trigger settings at 15 degrees offset) so my idle is very happy.

Brent GREAT DEPRESSION RACING 1992 Duster 3.0T The Junkyard - MS II, OEM 10:1 -[I] Old - 11.5@125 22psi $90 [U]Stock[/U] 3.0 Junk Motor - 1 bar MAP [/I] 1994 Spirit 3.0T - 11.5@120 20 psi - Daily :eyebrows: Holset He351 -FT600 - 393whp 457ft/lb @18psi 1994 Spirit 3.0T a670 - He341, stock fuel, BEGI. Wife's into kid's project. 1990 Lebaron Coupe 2.2 TI/II non IC, a413 1990 Spirit 3.0 E.S. 41TE -- 1993 Spirit 3.0 E.S. 41TE -- 1994 Duster 3.0 A543 1981 Starlet KP61 Potential driver -- 1981 Starlet KP61 Parts -- 1983 Starlet KP61 Drag 2005 Durango Hemi Limited -- 1998 Dodge 12v 47re. AFC mods, No plate, Mack plug, Boost elbow -- 2011 Dodge 6.7 G56