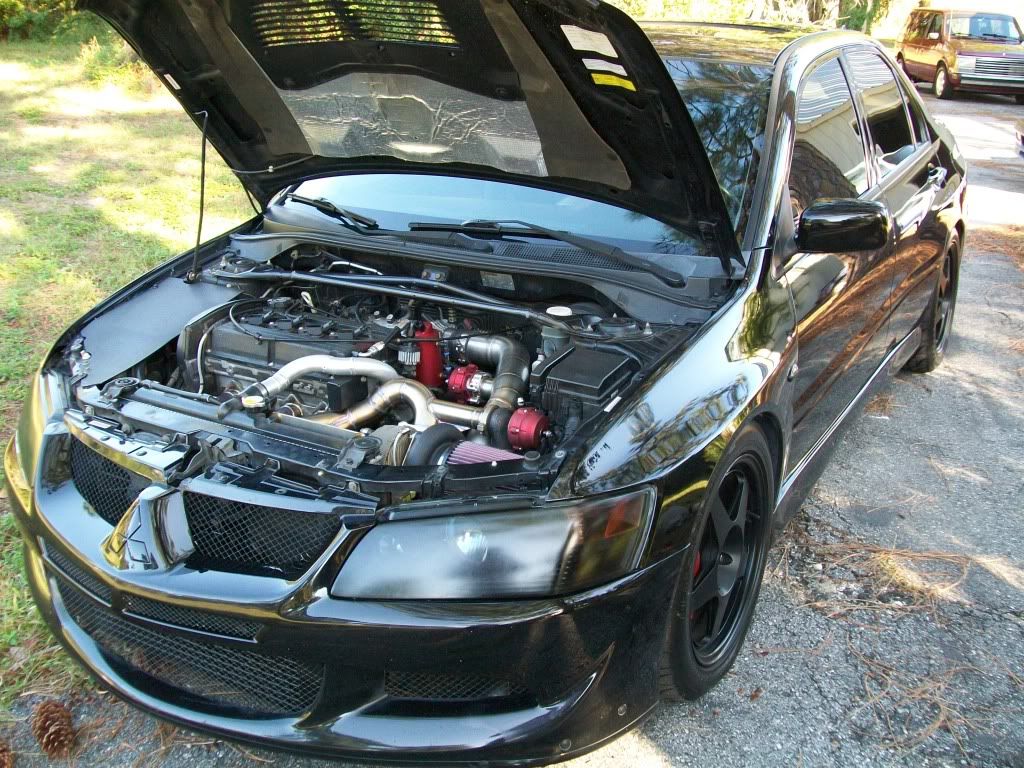

Well this will serve as a follow up to the thread about the van intercooler. This weekend my friend Zach and I got to work doing a GT35R setup on his Evo. We started on it early friday morning and finished it up to take it out to the local meet by saturday night at 9:30, so it went pretty damn well!

This will be mostly pictures, as there are a lot, start to finish.

Enjoy!

Getting the car situated in the AMotion garage...

As is, EVO9 turbo setup on a cheapie manifold...

Old IC plumbing we made had to move to allow clearance...

Me getting busy... gotta love the chair!

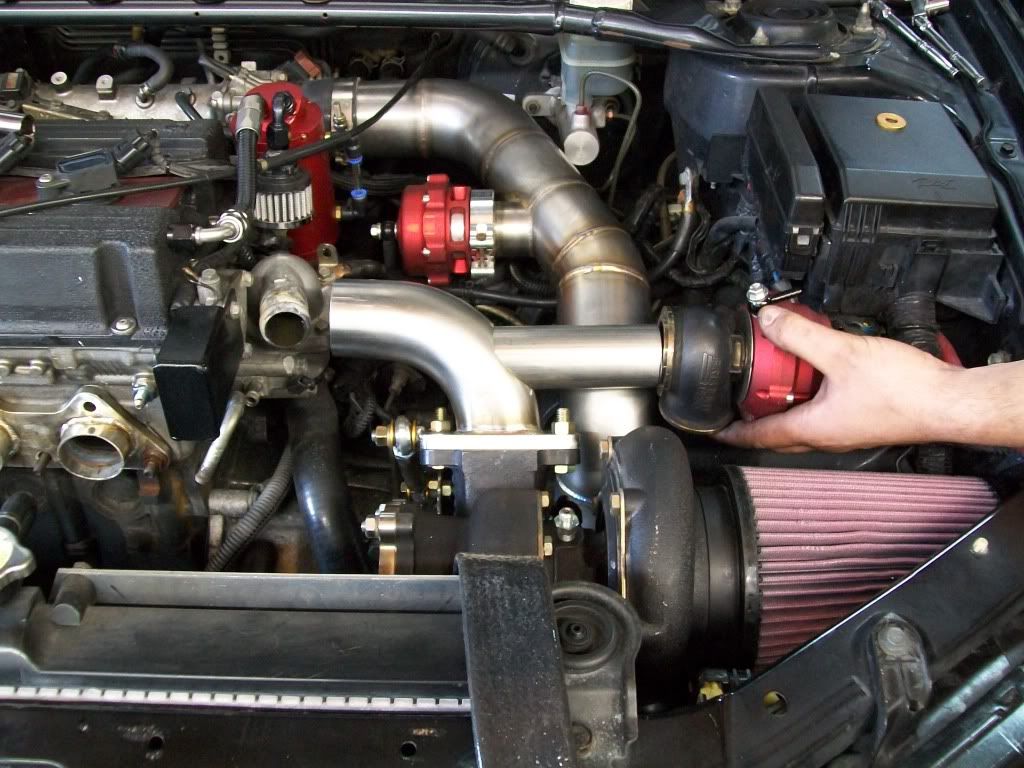

Turbo mock up positioning. At this point the heim joint brace was done, and the downpipe will be done first as the design of the header could prevent the DP from getting back under the oil pan if there wasn't room alloted for it. You have to remember order of operations in a full system build like this, so you don't end up having to change/cut stuff up afterwards.

Reply With Quote

Reply With Quote

Excellent work.

Excellent work.

but in a good way,

but in a good way,