I know I have mentioned these parts before in the Z's Update thread, however, after discussing these with Tommy, Jackson, etc. and since I just got some updated info and pictures today, I thought I'd just put it all in one thread.

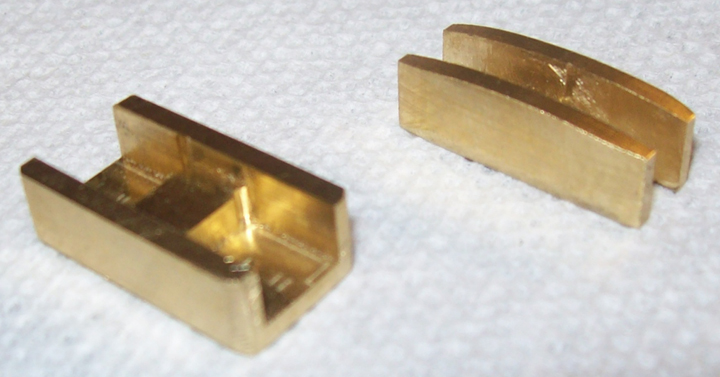

This thread is about Prototype Brass Shift Fork Pads for the A568.

Why brass? The original thought was that they would provide a more positive shift feel and they would be stronger and more durable than the stock plastic pads. Only concern is the frictional properties of brass vs. plastic in regards to the pads' secondary function of slowing the geartrain down between gears.

Brass pads CNC machined out of regular brass bar stock - specific grade unknown.

The test trans is a '91 A568 put together in 2008 with Brass pads on both the 1-2 and 3-4 shift forks leaving stock plastic ones on 5th.

The test vehicle is my '87 Shelby Z 2.4L ~500FWHP

Test prototypes have been subject to approx 200 miles including over 100 trips down the 1/4 mile, typically shifting at 7k RPM. Maybe a dozen of those runs included WOT shifting into 3 and 4.

I have not measured the wear but it is what I would call significant for the amoutn of use. I am contemplating if new plastic ones would have lasted as long or longer?

Pictures below show the stock and brass pads for comparison and current condition including wear.

Discuss.

Reply With Quote

Reply With Quote

)

)

Once setup with the molds and process, you can pop out thousands of pads for what it costs to machine one of them out of brass or any metal. There may be some wear advantages to plastic but it comes at a big cost: durability.

Once setup with the molds and process, you can pop out thousands of pads for what it costs to machine one of them out of brass or any metal. There may be some wear advantages to plastic but it comes at a big cost: durability.