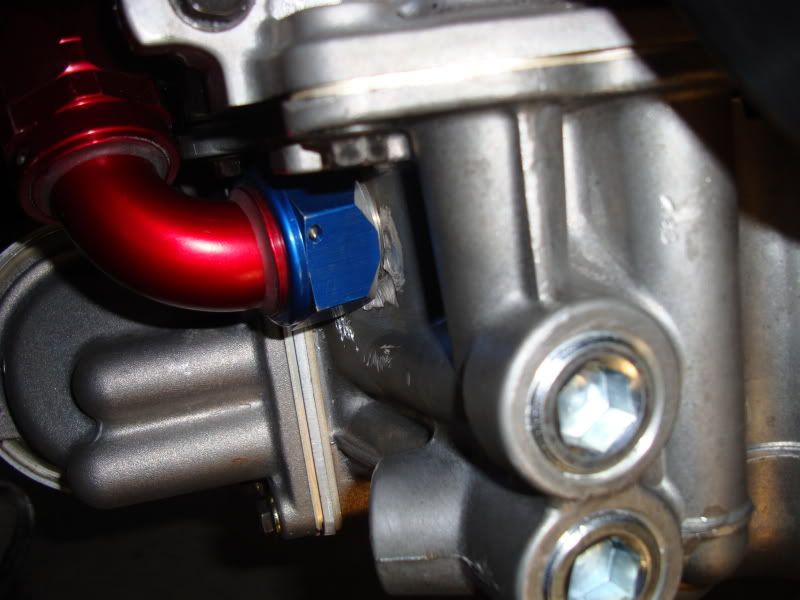

Where are you guys pulling oil pressure from on the 2.4L block to feed the turbo? I am using a 2.4 out of a 97 Stratus.

Also, I planning on running the oil return right into one of the drain back channels that are on the back side of the block. There is a factory npt fitting drilled right into the side of the channel that runs through the middle of the block. Is there any issue with using this fitting?

Reply With Quote

Reply With Quote

12.57@104 :O)

12.57@104 :O)