Originally Posted by

ShelGame

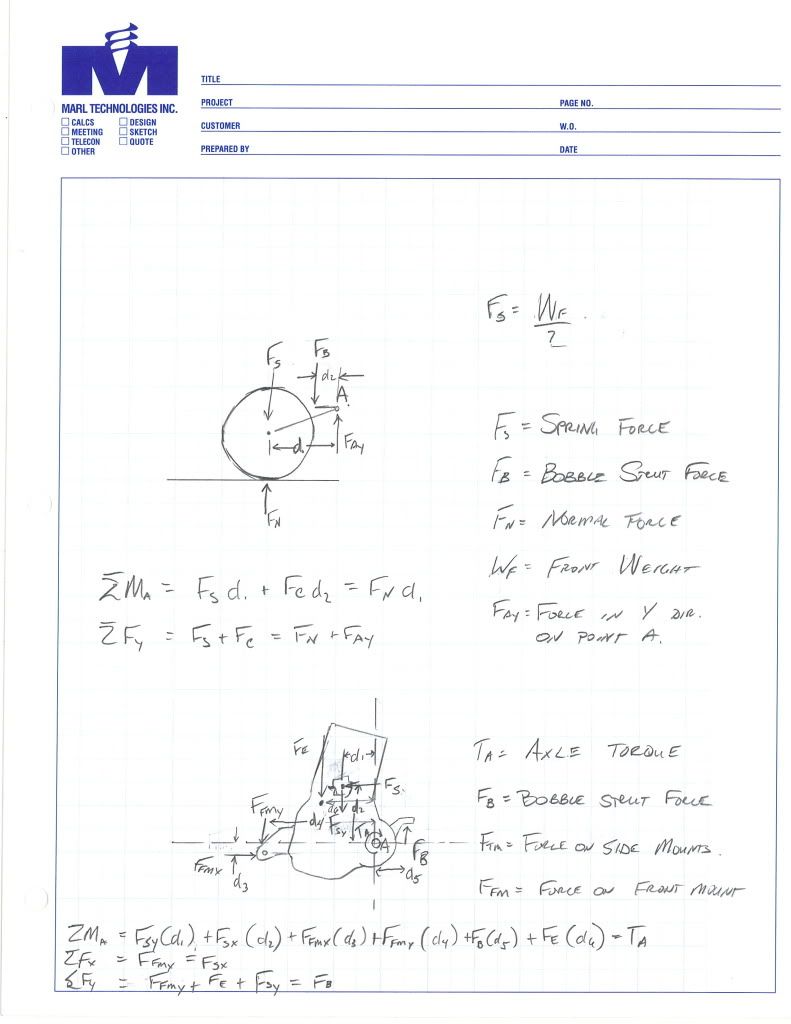

2) The linkage connection on the trans is below the axle centerline and well below the engine center of rotation (I'm guessing somewhere near the engine mounts). With the (apparent, hard to tell in pics) angle of the linkage, it looks like a dropping rate linkage - the linkage goes toward a toggle point. Of course, it doesn't move enough to actaully toggle, but that's the wrong direction, I think. Would be better as a rising rate linkage, at least that's what my intuition tells me. I could be wrong on that.

Reply With Quote

Reply With Quote

but Like Shel said below, it would be dificult to calculate the input force.

but Like Shel said below, it would be dificult to calculate the input force.