i had a feeling that you were going to say something about listening to knock via a detonation can or some sort of microphone.

ive been trying to get simon to do this on his van to adjust his timing.

you can record the sound and analyze it to determine the frequency then a bandpass filter can be constructed to interface the wide range sensor to more simple electronics. i think audacity can do fast fourier transforms to show frequency peaks.

ive been working on a knock box to compare the knock output of narrow range sensors (or wide range ones with a bandpass filter) to a preset curve with respect to RPM but since its summer the project has dropped off some cause im outside more. its completely tunable and datalogs knock voltage and RPM. hopefully i get trapped in the house some to work on it.

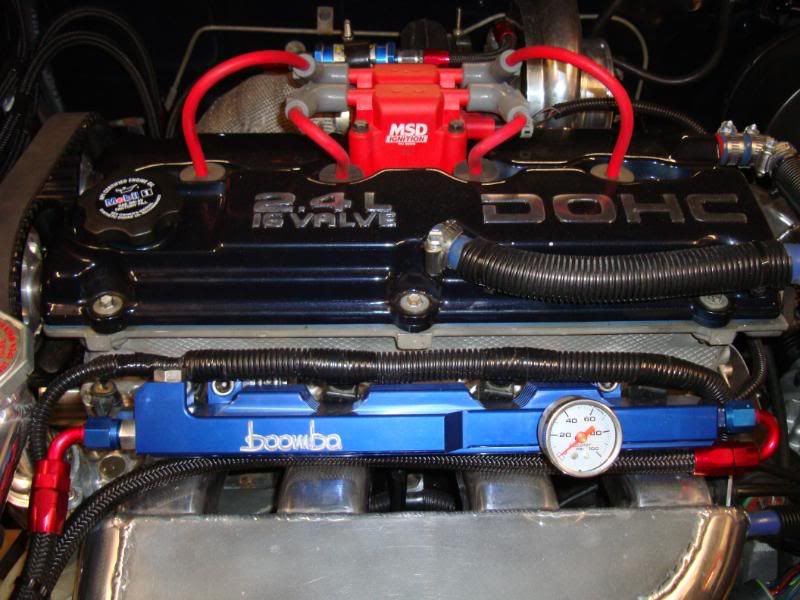

i just wish i had cyl by cyl timing control so that i could make each cyl knock independently via timing (in a safe manner... low or no boost) so that i could determine the best place to put a knock sensor so that the signal strength is the same from each cylinder. thats why the 8v motors have the sensor on the intake. it gave the most even signal from each cyl knock event. same with the location on the TIII motor. with the SRT motor, they have a specific table in the code that tells the knock threshold voltage per cylinder because the sensor doesnt "hear" equally from each cylinder. the voltage values in those tables are the same for cyl's 2 and 3 but less for cyl's 1 and 4.

Brian

Reply With Quote

Reply With Quote