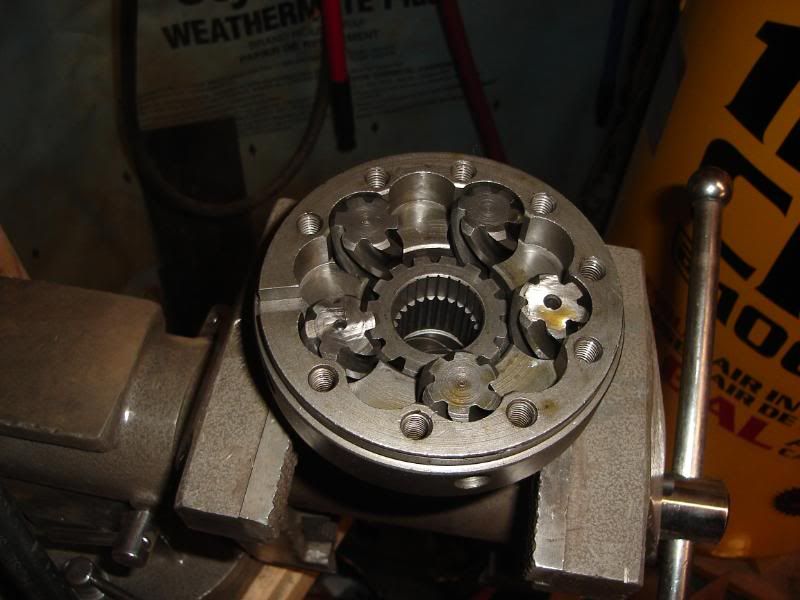

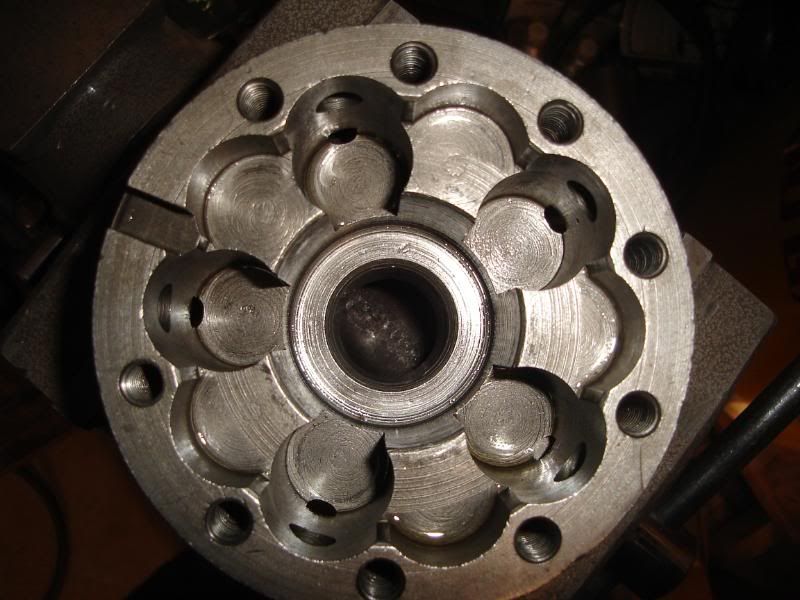

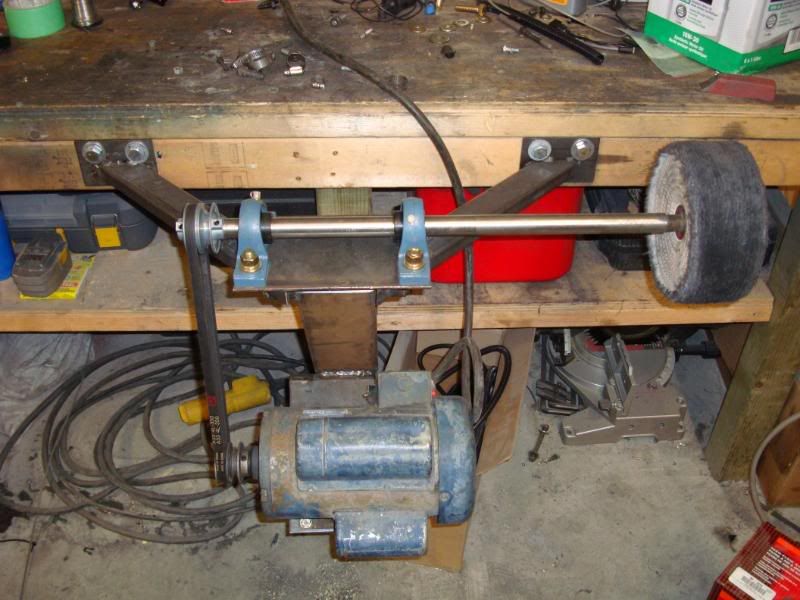

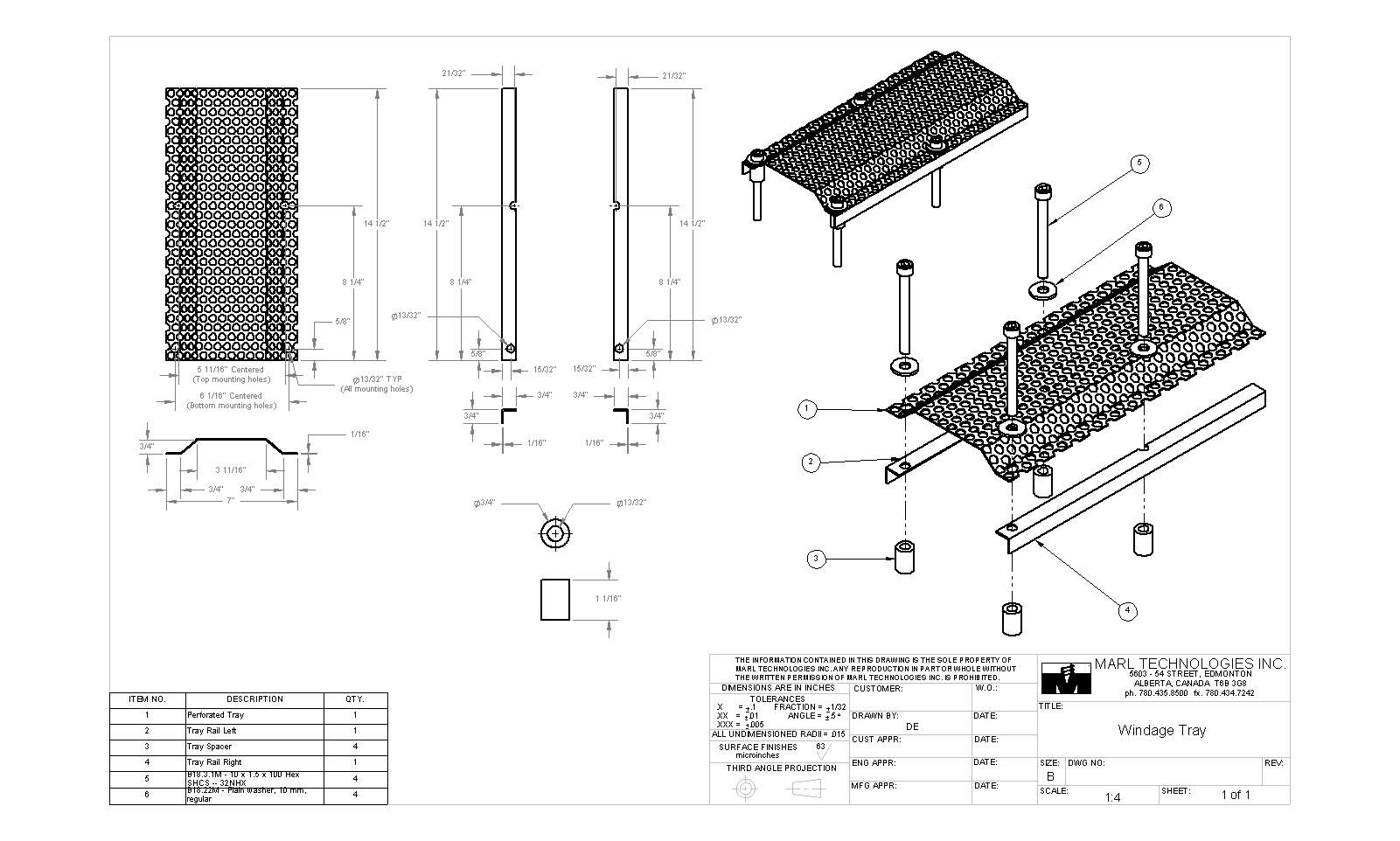

I received a request for dimensions on the windage tray I built so I made a model of it to get a drawing out.

***DISCLAIMER***This fit on my vehicle but in no way do I assure it will work on anything else. Use at your own risk. Please don't try to sue me if it doesn't work since I haven't even started my engine yet***DISCLAMER***

The only thing I forgot to add was I used sheet with 3/8" perforations. This is just a drawing of what I made for my engine which is a 2.4 from a stratus so be sure to take it with a grain of salt as you should with anything you get from the Internet. Make sure you take some rough dimensions of your engine or even make a cutout from card board to make sure it won't interfere with anything. Also notice that the front and rear mounting holes are not the same distance apart. The rear ones are closer together. I used 10x1.5x100mm socket head cap screws that screwed into the holes that the balance shafts used. I also needed to clearance the perforated sheet to clear the washers which isn't represented on the drawing. When flattened out the perforated sheet measures 14.5"x7.546" so that should give you a rough idea of what size you would need.

Here is a picture of the drawing but you can also go here ( http://www.mediafire.com/?fgncxr3ym2d ) to download a zipped e-file. Just unzip it and run the executable and it will let you look at the whole drawing as well as each individual piece by hitting the next button in the tool bar. You can also rotate and zoom in on the piece using the respective buttons in the toolbar. Hit home to take you back to the drawing. Hope this helps some one out.

***EDIT*** I forgot to mention that the perforated sheet is welded to the 2 L brackets. Please don't try to just bolt it all togther. I would think that is obvious but just incase. If you decide to just bolt it then please see the disclaimer above.***EDIT***

DJ

Reply With Quote

Reply With Quote . Good excuse to get new stuff though. It was only $125 to my door and it was custom molded with all the jute padding too. I am pretty happy with it for the price.

. Good excuse to get new stuff though. It was only $125 to my door and it was custom molded with all the jute padding too. I am pretty happy with it for the price.

) and I think the boxier style looks better with the Shadow body. I would like to go some where and see what the colors look like in real life though. Any one have any opinions??

) and I think the boxier style looks better with the Shadow body. I would like to go some where and see what the colors look like in real life though. Any one have any opinions??