Has anyone ever considered incorporating a pilot bearing onto one of the FWD trannies?

It seems that since I have been using 4 pucks that the input shaft bearings tend to go quickly. My thought is that much of this comes from the chatter that a 4 puck will produce combined with the frequency of use in daily driving. I can't help to think that some extra support closer to the clutch would help relieve some of the stress on the terrible design of using a tapered bearing on our input shafts.

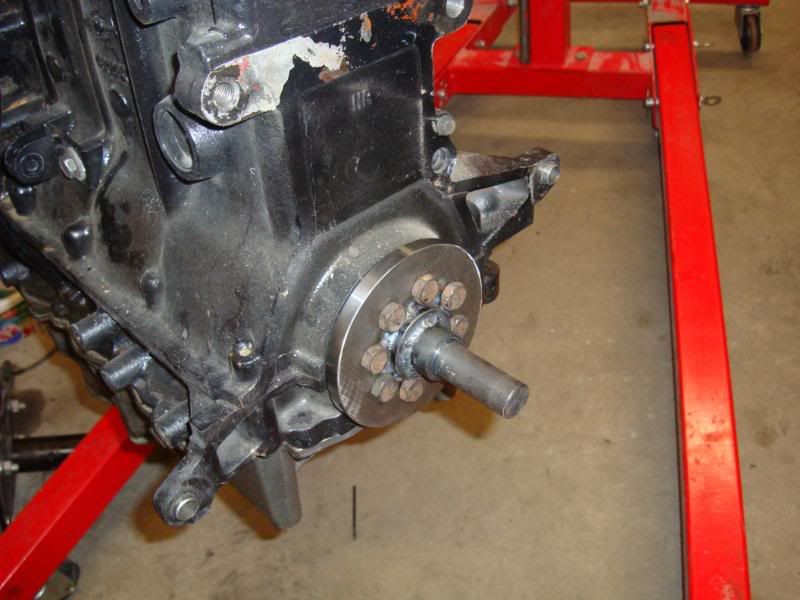

To make it possible I would need to weld some high carbon steel to lengthen the input shaft past the clutch and then incorporate the bearing into the crank. From what I can tell I could machine a piece to press into the current cank bore and use a toyota bearing like what some of the RWD guys are doing.

So I'm curious if this has crossed the minds of anyone else or if I'm missing something and the chatter isn't the cause of my IPS bearing problems.

DJ

Reply With Quote

Reply With Quote

If you close one eye and squint, the flywheel looks like it was kinda cut for one, or that's just extra space for the input shaft. Seems like the relief is larger than it would have to be...

If you close one eye and squint, the flywheel looks like it was kinda cut for one, or that's just extra space for the input shaft. Seems like the relief is larger than it would have to be...  ?

?

I bought a couple clutches with those telltale little laser cut reliefs on the cage corners, hope they're not at issue. I've twisted the center out of a Clutchnet and an OE style Sachs. BTW I am really liking my Yellow PP and stock organic style disc I put in the Rampage. Streetable like stock and holding the 75 shot on 8.5" slicks no problem

I bought a couple clutches with those telltale little laser cut reliefs on the cage corners, hope they're not at issue. I've twisted the center out of a Clutchnet and an OE style Sachs. BTW I am really liking my Yellow PP and stock organic style disc I put in the Rampage. Streetable like stock and holding the 75 shot on 8.5" slicks no problem